Welcome

Integrated Supply Chain Solutions offers supply chain management consulting services that primarily focus on optimizing the manufacturing processes of food companies. Additionally, we provide advisory services to private equity (PE) firms.

Our business in Ponte Vedra Beach, Florida is predicated on an integrated business approach. This includes how supply chain processes functionally interact with the business as a whole and not as separate entities within the business.

Why Work With Us?

We have extensive executive experience advising various blue chip food companies, and have had total responsibility for the business unit supply chain that would eventually became the most successful operating company within Unilever’s global ice cream business. If you want to take your food, dairy, or beverage processing company or PE firm to the next level, please contact us today!

Integrated Supply Chain Solutions: Business Philosophy and Services

The basic philosophy and practice of the firm revolve around the view that no function, including the supply chain, should operate independently within the business and its operating structure. In our view, the best approach is to employ an integrated planning and operational model where there is full alignment of the strategic plan with the operational plan to eliminate “silo” behavior wherever possible. It is important to use an integrated platform that can act as a forum for cross-functional success within the organization. A clear directional strategy will help in restoring the balance within the company so that high performance can be achieved at the factory level, resulting in lower costs, higher margins, and the full organizational understanding of the manufacturing drivers that exist to support the strategy, not just react to it.

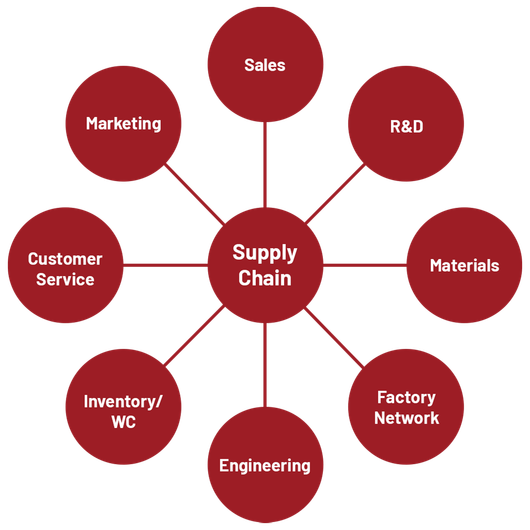

When all is said and done, ingraining a cross-functional mutual objective approach into the fabric of the business, making the organization as seamless as possible, will provide better understanding of manufacturing costs and capabilities, leveraging supply chain skills to satisfy customers while lowering costs at the factory level. Thinking of the organization as a whole, we have inserted this graphic for review.

Getting optimized business performance means, almost by definition, optimizing supply chain performance. One of the elementary components for a high-performing supply chain is a robust set of planning processes. We see repeatedly in conversations with business partners a yearning for improved sales and operations planning processes (S&OP), demand planning programs, supply planning that optimizes factory performance, and the desire for better inventory and working capital management.

It should go without saying that all of the functions in an organization must accurately reflect the strategic objectives of the business. But with an eye on superior supply chain performance, another way to look at supply chain is as a hub where each spoke connects to a function, all of which are reliant on a sound supply chain platform.

In an era of JIT, vendor-managed inventory, and resource constraints, excess costs via waste can make a significant difference in company performance and customer perception. Integration of the supply chain into the business model provides a platform for overall success in a way that isolating the function cannot. When the entire company understands the linkages between business capabilities, innovation objectives, and customer requirements, it stands to reason that superior decisions and direction will be taken. It also provides a clearer view of risk taking and risk management.

A business operates in two key dimensions: internal and external. In neither dimension should a company allow itself to get out of balance. A focus on brand building should not force the company to forego the opportunities derived from technology or manufacturing advantages. Nor should a focus on cash and working capital work against the optimal flow of materials and labor that make for a high-performance supply chain. It should go without saying that all of the functions in an organization must accurately reflect the strategic objectives of the business. But with an eye on superior supply chain performance, another way to look at supply chain is as a hub where each spoke connects to a function, all of which are reliant on a sound supply chain platform.

The following areas are a source of evaluation and improvement for Integrated Supply Chain Solutions:

- Improper Demand Planning and Forecasting

- Supply Management and Purchasing/MRP Inefficiency

- Finished Goods Inventory in the Wrong Place Geographically

- Wrong Product Mix for Optimized Customer Service

- Improper Supply Plans

- Sub-Optimal Production Line Scheduling/Line Utilization

- Increased Material Waste and Conversion Loss

- Sub-Optimal Manufacturing Productivity/Output